Description

PACIFIC ELESAFE SILICON 220R GREASE represents the latest technology in lubrication. It is formulated from pure silicone base oils and selectively treated with rust, oxidation and anti-wear additives coupled with a shear stable thickener to provide maximum parts protection in a wide range of temperatures from -50°F to 570°F (-45°C to 298.8°C). Primary properties of PACIFIC ELESAFE SILICON 220R GREASE are that it is non-melting, has a high dielectric strength, low volatility and is insoluble in water, methanol, ethanol, dilute acids, caustics, glycol, glycerine, vegetable and mineral oils.

It is designed to be compatible with most plastics and rubbers, especially ethylene propylene terpolymer (EPDM, EPT) commonly used in Disc Brake Caliper systems. It is also NSF/U.S.D.A. H-1 *Registered and KOSHER approved, which gives it full acceptability for use in ALL areas where incidental food or potable water contact may occur.

Advantages

- Prevents Rust and Corrosion

- Chemical Resistant

- Wide Temperature Range

- High Dielectric Strength

- Meets MIL-S-8660C Specifications

- Non Melting

- Extremely Low Volatility

- Waterproof, will not washout

- Reduces Wear

- *NSF H-1 Registered and KOSHER Approved

Usage

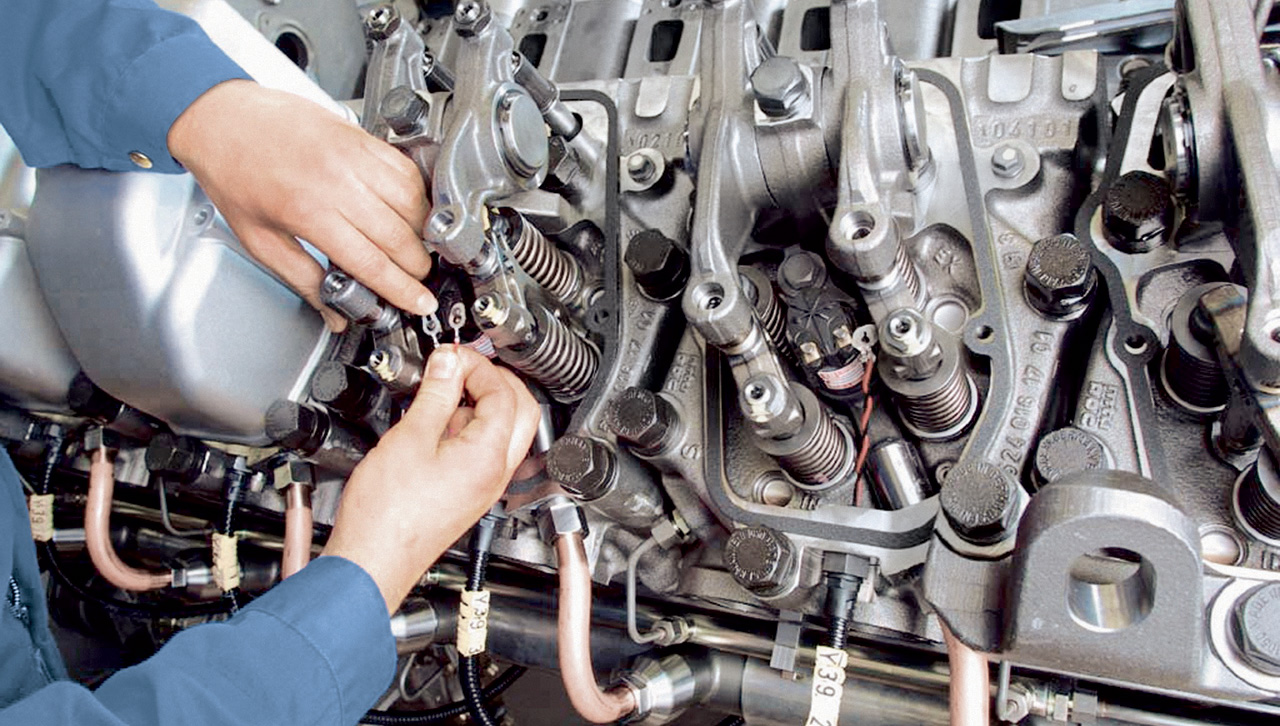

PACIFIC ELESAFE SILICON 220R GREASE was originally designed as a problem solving, anti-corrosion lubricant for all moving caliper hardware, backing plates and seals of Disc Brake Caliper assemblies. However, due to its water, chemical and corrosion resistance capabilities it is an excellent choice in a wide variety of automotive, marine, agriculture, household and industrial applications. Some of its uses include:

- Disc Brake Calipers

- Brake Hardware

- Spark Plug Boots

- Battery Terminals

- Electrical Connections

- Weather Stripping

- Gaskets and O-Rings

- Valves

- Slides and Ways

- Pool Equipment

- Bushings

- Motion Controllers