Description

PACIFIC ELESAFE CERAMIC DBC GREASE is formulated from pure synthetic base oils and treated with the latest rust, oxidation and anti-wear additives to provide lasting protection against friction, wear and corrosion. It is fortified with a high concentration of a unique, high temperature ceramic boundary lubricant that will stay in place and protect at extreme temperatures from -50°F to over 3000°F. while providing protection against dirt, corrosion and uneven pad wear.

PACIFIC ELESAFE CERAMIC DBC GREASE was designed to be compatible with most plastics and rubbers, especially ethylene propylene rubber (EPDM, EP or EPT) commonly used in Disc Brake Caliper systems. The distinctive Purple color makes it easy to identify during and after application.

Advantages

- Prevents Rust & Corrosion

- Silences Calipers

- Waterproof, will not washout

- Lasts the life of the Pads and Shoes

- Non-Melting

- Chemical Resistant

- Wide Temperature Range

- Reduces Wear

Usage

PACIFIC ELESAFE CERAMIC DBC GREASE was originally designed as a high performance problem solving, anti-wear and anti-corrosion lubricant for all moving caliper hardware, backing plates and seals of Disc Brake Caliper assemblies. Because it is a pure synthetic, high concentration dry-film, boundary lubricant it is a superior noise dampening compound that will last the life of the brake pads and shoes thus reducing customer comebacks resulting from noise complaints.

Directions

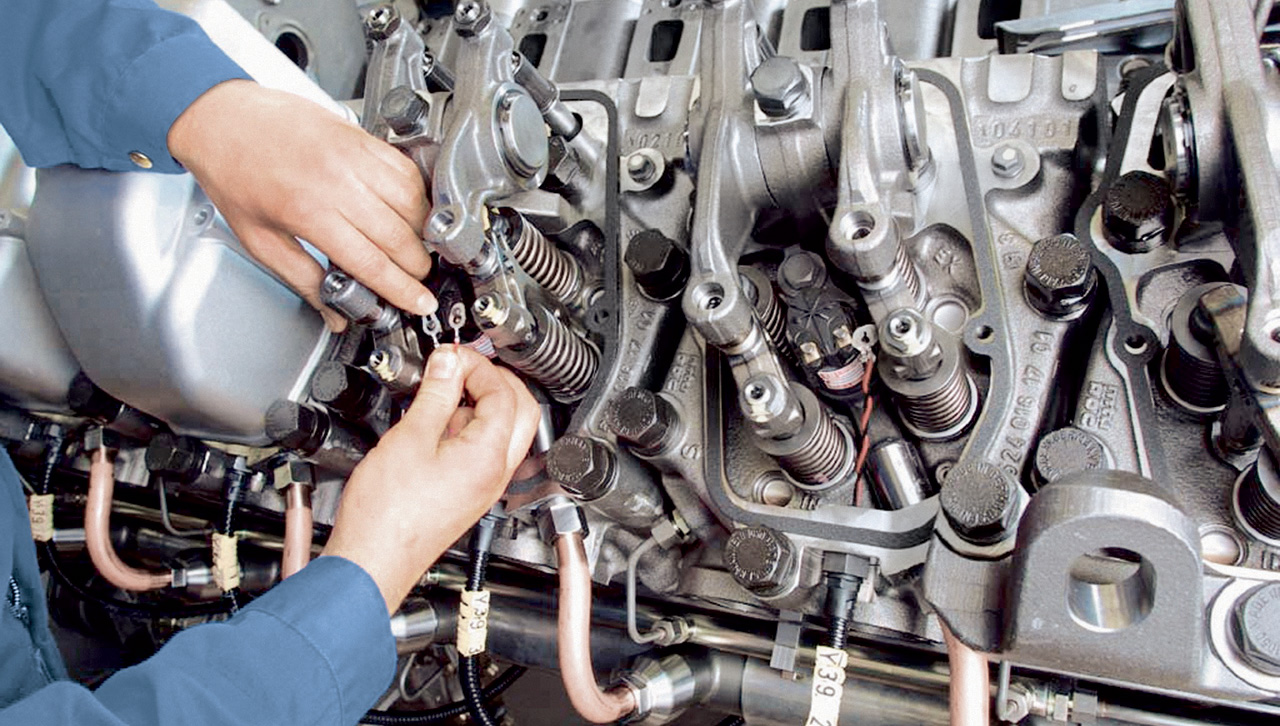

Wire brush the caliper housing and anchor plate to remove all dirt and dust. Apply PACIFIC ELESAFE CERAMIC DBC GREASE to all moving caliper hardware, mating surfaces and steel backing plates of the disc brake pads. Any excessive grease squeezed out from between mating surfaces must be removed. Keep Lubricant off pads and rotors.